PCB Connectors: A Comprehensive Guide to the Different Types and Their Applications

PCB connectors are an essential part of any printed circuit board (PCB) design, as they provide a means of connecting the various components on the board to external devices or other PCBs. They come in a wide range of shapes, sizes, and types, each designed for specific applications and requirements. In this article, we will delve into the various types of PCB connectors and discuss their key features, applications, and benefits. We'll also include some real-life examples of how these connectors are used in various industries.

Introduction to PCB Connectors

PCB connectors are used to connect the various components on a PCB to external devices or other PCBs. They come in a wide range of shapes, sizes, and types, including USB-C connectors, circuit board connectors, thermocouple connectors, PCB mount sockets, power connectors, ribbon connectors, and header connectors. Choosing the right connector for your PCB design can be challenging, as there are many factors to consider such as size, performance, and cost. In this article, we'll provide a comprehensive overview of the different types of PCB connectors to help you make an informed decision.

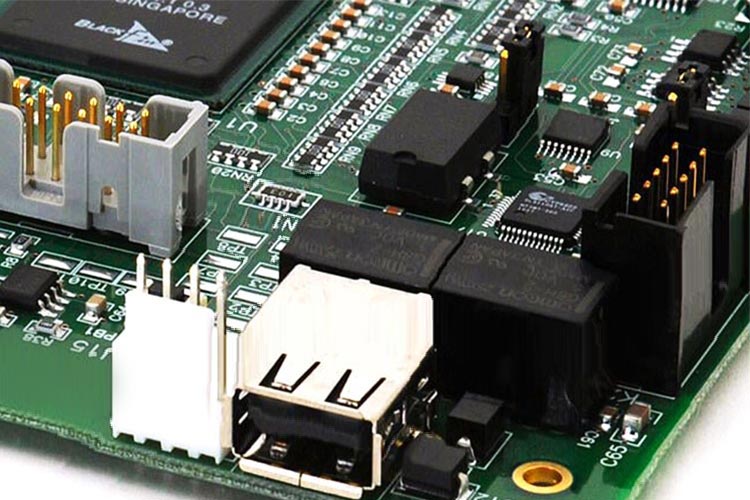

Circuit Board Connectors: Connecting Your PCB to the World

Circuit board connectors, also known as board-to-board connectors, are used to connect PCBs to other PCBs or external devices. They come in a variety of shapes and sizes, and can be used for a wide range of applications. Some common types of circuit board connectors include:

- Pin headers: These connectors consist of a row of pins that are soldered to the PCB. They are commonly used for connecting PCBs to external devices such as sensors and actuators.

- Socket connectors: These connectors are used to connect two PCBs together. They consist of a row of sockets on one PCB that mate with a row of pins on the other PCB.

- Edge connectors: These connectors are used to connect PCBs to external devices such as backplanes or daughterboards. They consist of a row of pins or sockets that are mounted on the edge of the PCB.

Circuit board connectors are commonly used in the industrial, automotive, and aerospace industries, as well as

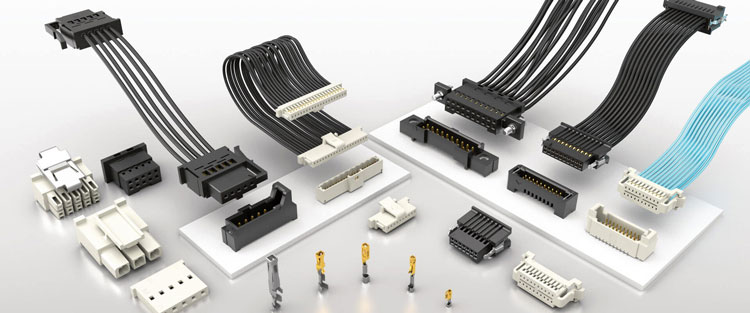

Ribbon Connectors:

Ribbon connectors are a type of connector used in PCB design to connect the PCB to external devices or other PCBs. They consist of a flat ribbon-like cable with a series of conductive wires running parallel to each other, and are commonly used for data transfer, communication, and power transmission. There are several types of ribbon connectors available, including IDC connectors, FFC/FPC connectors, and pin connectors. One of the main advantages of ribbon connectors is their ability to carry a large number of signals in a small space, making them ideal for use in high-density applications. So next time you're working with a PCB, don't forget to consider using a ribbon connector to make those connections!

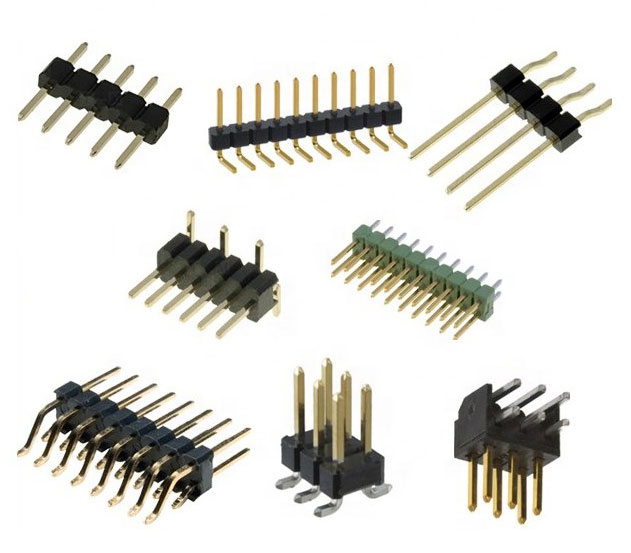

Header Connectors:

Header connectors are a type of connector used in PCB design to connect the PCB to external devices or other PCBs. They consist of a row of pins or sockets that are soldered to the PCB, and are typically used to make connections between the PCB and external devices such as sensors, actuators, and displays.

Header connectors come in a variety of shapes and sizes, and can be used for a wide range of applications. Some common types of header connectors include single row header connectors, double row header connectors, and right angle header connectors. Single row header connectors consist of a single row of pins or sockets, while double row header connectors consist of two rows of pins or sockets. Right angle header connectors are used when the connection needs to be made at a right angle to the PCB, such as in tight spaces or when the PCB is mounted vertically.

One of the main advantages of header connectors is their simplicity. They are easy to use and require minimal assembly, making them a popular choice for many PCB designs. So next time you're working with a PCB and need to make connections to external devices, consider using a header connector to get the job done!

USB-C PCB Connectors: The Reversible Connector for the Modern Age

If you've ever struggled to plug in a USB connector the right way, then you'll love USB-C connectors. These connectors are designed to be reversible, meaning they can be plugged in either way. They are commonly used in smartphones, laptops, and other devices to connect to peripherals such as printers, keyboards, and external hard drives. But USB-C connectors aren't just for consumer electronics - they are also used in PCB design to connect the PCB to external devices.

USB-C connectors are becoming increasingly popular in a variety of industries due to their high-speed data transfer capabilities and versatility. In the medical industry, they are used to connect medical devices such as heart rate monitors and blood pressure monitors to PCs and laptops for data analysis and storage. In the automotive industry, they are used to connect in-car entertainment systems and GPS navigation systems to the car's main computer system. And in the aerospace industry, they are used to connect various avionics systems to each other and to external devices.

Types of PCB Connectors based on Applications:

Reversible connectors are connectors that can be inserted into a receptacle in either direction, eliminating the need to align the connector with the receptacle. This makes them convenient to use and reduces the risk of damage to the connector or receptacle. Some examples of reversible connectors include USB-C and micro USB connectors.

Medical device connectors are connectors specifically designed for use in medical devices. They must meet strict requirements for reliability, durability, and sterilization. Some common types of medical device connectors include DIN connectors, circular connectors, and mini connectors.

Automotive connectors are connectors specifically designed for use in the automotive industry. They must meet strict requirements for reliability, durability, and performance in harsh environments. Some common types of automotive connectors include OBD connectors, ECU connectors, and battery connectors.

Aerospace connectors are connectors specifically designed for use in aerospace applications. They must meet strict requirements for reliability, durability, and performance in extreme environments. Some common types of aerospace connectors include circular connectors, rectangular connectors, and coaxial connectors.

Industrial connectors are connectors specifically designed for use in industrial applications. They must meet strict requirements for reliability, durability, and performance in harsh environments. Some common types of industrial connectors include circular connectors, rectangular connectors, and terminal block connectors.

Data center connectors are connectors specifically designed for use in data centers. They must meet strict requirements for reliability, durability, and performance in high-density environments. Some common types of data center connectors include fiber optic connectors, coaxial connectors, and modular connectors.

Types of PCB Connectors based on Design

High-speed connectors are connectors specifically designed for use in high-speed applications. They must meet strict requirements for reliability, durability, and performance in high-speed environments. Some common types of high-speed connectors include fiber optic connectors, coaxial connectors, and modular connectors.

Low-profile connectors are connectors with a low profile, meaning they have a small height or thickness. They are used in applications where space is limited or where a low profile is desired for aesthetic or functional reasons. Some common types of low-profile connectors include surface mount connectors, board-to-board connectors, and cable-to-board connectors.

Waterproof connectors are connectors specifically designed to be resistant to water. They are used in applications where the connector may be exposed to water or other liquids. Some common types of waterproof connectors include circular connectors, rectangular connectors, and terminal block connectors.

Solderless connectors are connectors that do not require soldering for assembly. They are used in applications where soldering is not practical or where the connector needs to be easily removable. Some common types of solderless connectors include wire connectors, terminal block connectors, and board-to-board connectors.

Comments